- Product Overview

- Technical Specifications

- Resources

- Accessories

-

Construction and service companies as well as civil and structural engineers can now improve the way they locate rebars, voids, post-tension cables, cavities, conduits, and any other objects buried in the structure before cutting or drilling into the concrete.

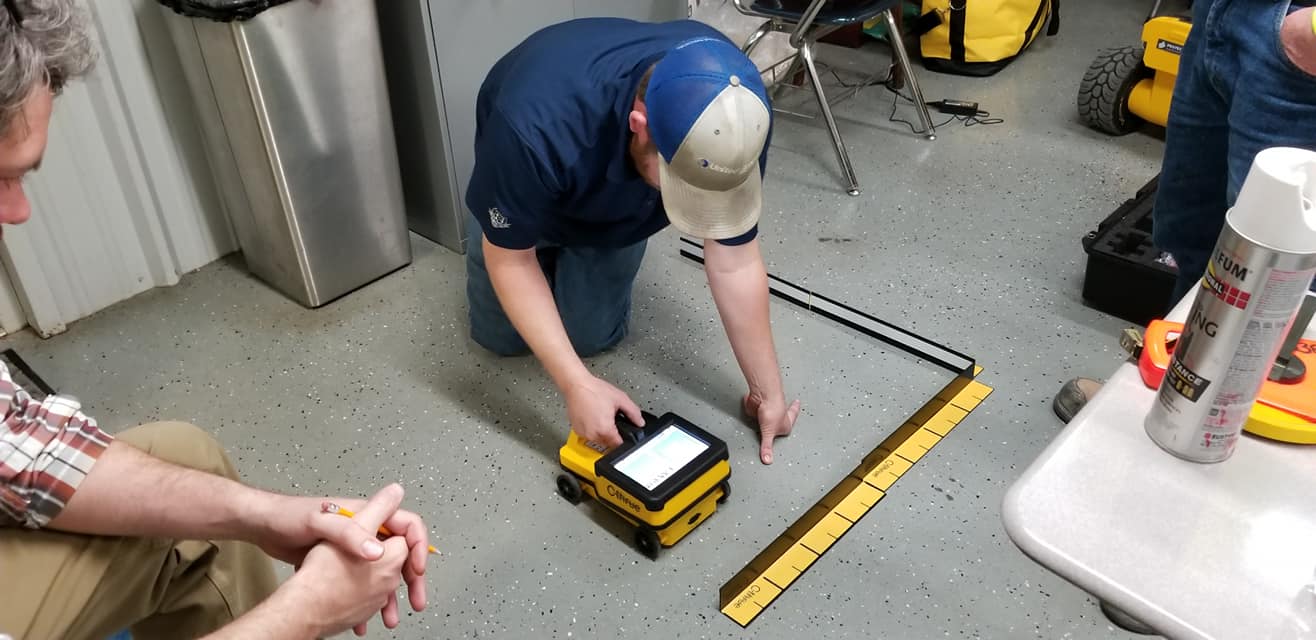

C-thrue is an easy-to-use and robust solution to see through concrete structures and reveal true data that lead to optimal decision-making. The solution is suited for all construction sites and operations including building renovation, overpasses, monuments, bridges and tunnels surveys, as well as for detailed analysis of the original engineering project and comparison with the as-built structure.

Today, C-thrue offers more flexibility with no limitations for your analysis requirements, thanks to a compact and light telescopic pole and an external controller that can be easily transported on site in challenging locations or conditions (e.g. under a deck, along vertical walls, etc...).

The C-thrue external controller allows easier and faster data interpretation thanks to real-time data processing and representation of results in Augmented Reality for more efficient decision-making.Features and Benefits:

-

Clearer and faster surveys

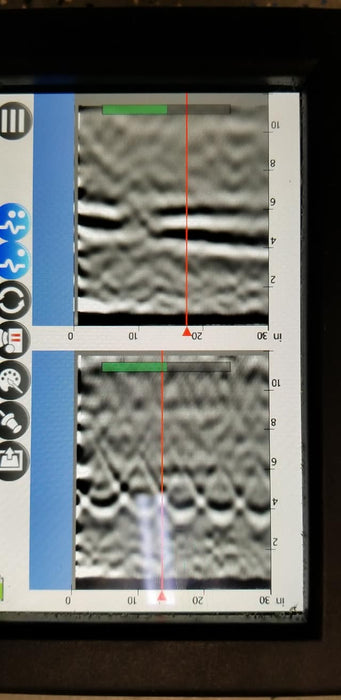

Detection of both first and second levels of rebars thanks to the system’s double polarisation. -

Safe drill in the surveyed structure

Rebar/void automatic insight capabilities that improve safety before cutting or drilling into the concrete. -

Fully-visible, multi-touch display

Data displayed on the screen are never obscured by the handle or the user’s hand. -

Simplified data interpretation

Optimal decision-making supported by visualisation of acquired data in 3D models. -

Increased data accuracy

Eliminate manual, error-prone paper grids with an automatic positioning and navigation system. -

Advanced data visualisation

Augmented reality for 3D data visualisation and sharing across operators – in real time or intervals after acquisition. -

Automated data acquisition and analysis

Automatic detection of the first layer of rebars and result exportation. -

Flexibility everywhere

Lightweight, compact, drop resistant and transportable system for every user operations and construction sites.

-

Clearer and faster surveys

-

Technical Specifications

Antenna Center Frequency 2.0GHz Number of Antennas 4 Antenna Polarisation Horizontal and Vertical Number of Radar Channels 2 Scan Interval Up to 10 scans/cm Depth Range Up to 80cm (up to 31.5in.) Display Modes B-scan and C-scan (radar tomography) Positioning System "Virtual Pad" (based on 3 High safety - Class 1 laser sensors with reflective bars) AC Power Conduits Detection EM Sensor Integrated (50/60 Hz) Battery Li-ion Battery, 15V, 3.2Ah, 3-hour runtime Data Storage 32GB Connectivity USB, Wi-Fi Mechanical Specifications

Dimensions (Length X Width X Height) 285mm X 200mm X 160mm (11.2in X 8.6in X 6.3in) Weight 2.4kg (5lb) with battery Display 7.0 inches TFT multi-touch Environmental Specifications

Operating Temperature -20°C to +50°C (-4°F to +122°F) Storage Temperature -40°C to +60°C (-40°F to 140°F) Environmental IP65 Software Specifications

C-Thrue Software - Quick Start-up

- Real time radar data acquisition, processing and visualization in B-Scan

- Real time feature marking, management and editing tool

- Rebar/Void automatic discrimination

- VirtualPad - Positioning and navigation system

- Visualization of C-scan (radar tomography)

- Real time diagnose of radar and the other devices

- Metric and imperial units

- Availble in more than 20 languages

- First rebar layer automatic detection

- Automatic job reports

- Real time Power conduit sensing display

-

Links

- List